Aurora DM-110h

Inline Non-Contact Emitter Sheet Resistance Measurement

The DM-110h accurately and reliably measures emitter sheet resistance inline at full production speeds. The sensor uses safe reflected infrared light to produce high-resolution

characterization of emitter sheet resistance on a crystalline silicon wafer.

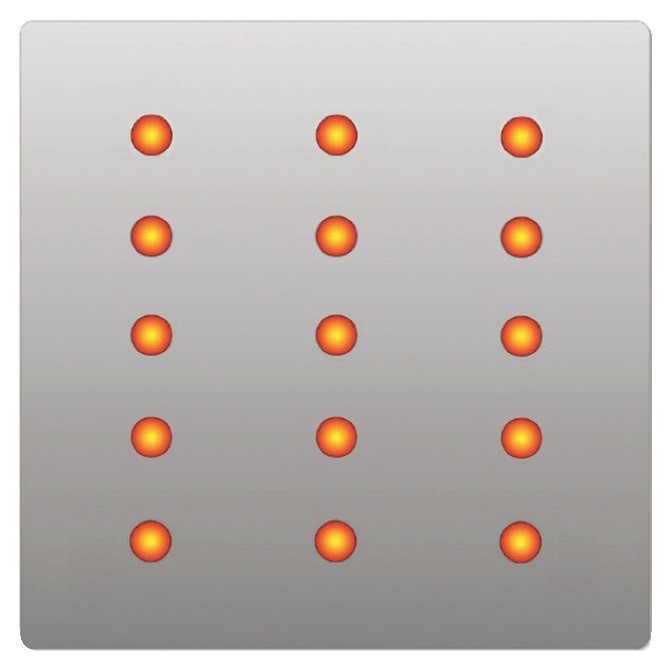

Representative Measurement Pattern

Description

The DM-110h measures the emitter sheet resistance within crystalline silicon photovoltaic (PV) wafers. This innovative product is the industry’s most accurate and reliable non-contact measurement tool that

characterizes diffusion and annealing process results. It rapidly performs measurements on a pattern of

discrete points on each wafer, as presented by an automated wafer handling system. Its patented technology

provides accurate real-time measurements for process control and optimization.

The system integrates with Aurora’s Visualize™ quality control system and with furnace automation to align

measurements with the wafer positions in each batch. This provides real-time visualization of furnace

performance, both spatially and in time, enabling optimal control and tuning of the diffusion process.

Features

- Non-contacting emitter sheet resistance measurement

- Designed for sample-based wafer measurement

- High-speed measurements with wafer mapping capability

- Intuitive graphical user interface

- Rock-solid long-term measurement stability

- Automatic measurement triggering

- Highly accurate and repeatable

Benefits

- Allows true characterization of both short- and long-term diffusion furnace behavior

- Eliminates operator error and inconsistencies in offline measurement

- Minimizes wafer damage caused by handling and four-point probe contact measurement

- Reduces labor costs associated with offline sampling and SPC charting

- Rapid payback

Specifications