Aurora Visualize™ ADM™ Control

Real-time Feedback Process Control for Emitter Diffusion

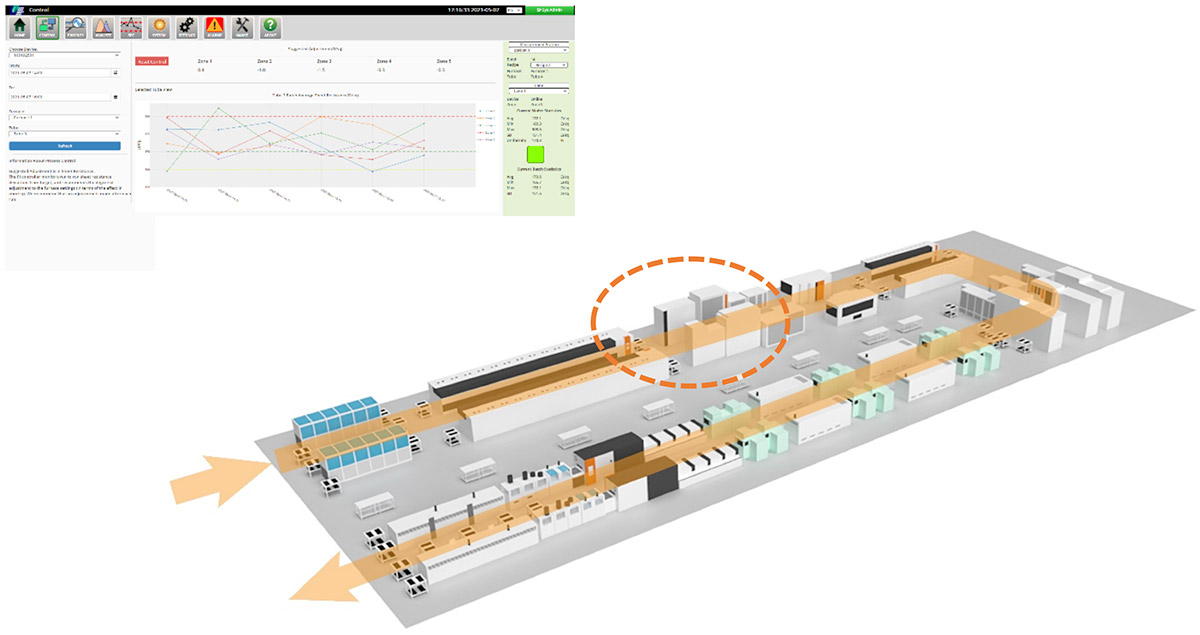

Aurora’s new ADM Control feature available in our Visualize product provides operators and process engineers with direct process control information using time-series sheet resistance data. This enables PV cell manufacturers to easily manage and control the performance of emitter formation with a complete understanding of process dynamics, batch after batch.

Diffusion process teams use batch-by-batch sheet resistance measurements to monitor and control variations in the furnace tubes. The wafer yield (percentage of wafers deemed satisfactory) is a key performance indicator for the team.

In many cases, wafers from each batch are sampled by a sheet resistance measurement device. If the sheet resistance falls outside of the specification limits, an alarm is raised, and these wafers are then re-scanned offline which is a laborious process. The process team is notified, and the diffusion furnace may then be “tuned” on a zone by zone basis to produce more desirable sheet resistance.

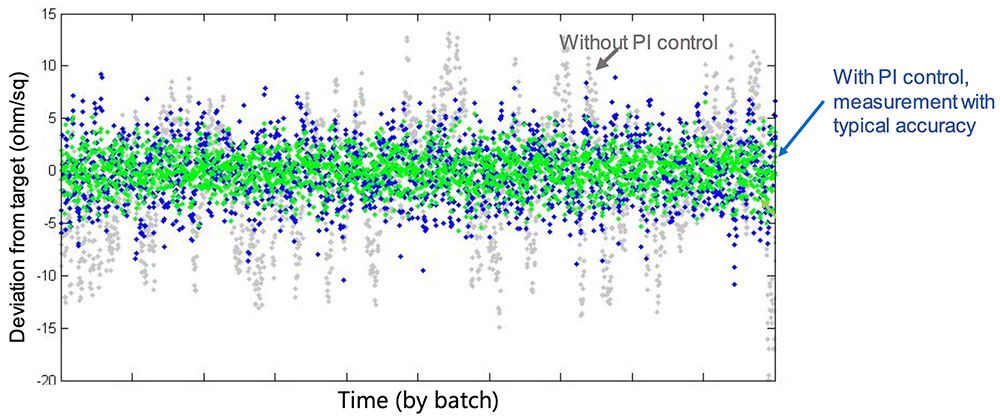

ADM Control automates this time-consuming manual process by tracking sheet resistance variations over time and applying our proprietary proportional-integral (PI) algorithm that determines the optimal amount to change the sheet resistance in each zone. The positive effect on sheet resistance stability can be seen below.

ADM Control also automatically accounts for measurement errors, allowing excellent sheet resistance control in the face of “real-world” instrumentation and production conditions.

Features

- Control chart showing timeline of diffusion furnace results by tube and temperature zone

- Zone-by-zone sheet resistance adjustment recommendations for each batch

- Built-in “key performance metrics” that enable process variation reduction and make end-of-line IV results more consistent

Benefits

- Reduction in unwanted cell quality variation

- Higher average cell efficiency due to reduced downgraded cell production

- Faster furnace ramp-up (initially and after maintenance)

- Increased production line throughput

- Rapid payback

ADM Control is available as a feature in Aurora’s server-based1 Visualize software product. It is easily and securely installed and made to operate in your cell production facility. It communicates with Aurora’s DMTM measurement systems and provides a web-based user interface for plant-wide access and usage.