Aurora Insight™

Industry 4.0 compliant real-time analysis to boost PV cell production yield and throughput

Aurora Insight gives process engineers and production personnel unprecedented power to easily and rapidly optimize and control PV cell production yield by quantitatively linking IV results to controllable upstream process characteristics in real-time.

Description

The quality imperative demanded in high-efficiency PV cell designs is to make exactly the same product, every single time, consistently meeting the designed performance specification. This means that understanding and controlling variations in production that affect the distribution of IV parameters is crucial. Insight uses the large volumes of PV cell production line data generated during End-of-Line (EOL) finished cell testing to provide you with actionable real-time information on your process equipment to control these variations. With Insight you can ramp-up production confidently and quickly, perform production line optimization with less experimentation and downtime, and detect and correct faults and process excursions more reliably and quickly. This enables you to boost your manufacturing yield and detect hidden process behaviours that affect product quality – increasing profits through optimal operation of your cell production, while reducing downstream costs and warranty liabilities.

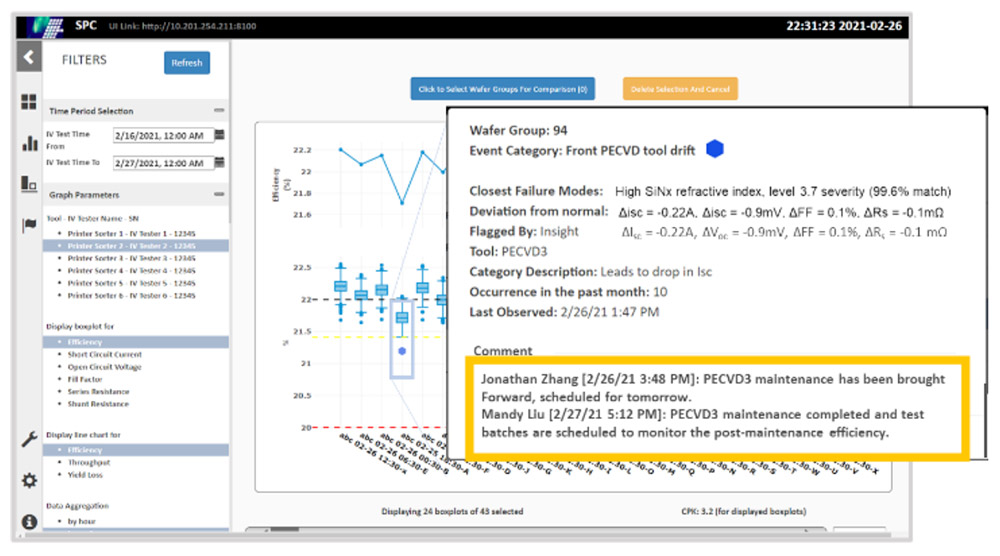

Rapid Detection and Correction of Yield Crashes

Impairments of optimal fabrication plant operation usually manifest as “yield crashes”, where a reduction in finished cell efficiency occurs. These can be difficult to resolve (intermittently occurring or with time spans from hours to months!) and can rapidly amount to high costs and significant yield reductions. Insight provides powerful, easy-to-use tools that allow you to respond more quickly and effectively to detect, characterize and correct the production faults or errors that cause such yield crashes.

Cost-Effective and Low-Impact Recipe Tuning

Continuous improvement to obtain the highest possible yield in a production line is a vital activity. However there are associated costs that are potentially large and sometimes hidden, such as unnoticed mistuned tools after a recipe change. Other costs include labour associated with planning, designing, executing, and analysing new recipe experiments, the use (and waste) of raw materials, and lost production time. Insight automates much of these activities with the least possible impact on steady-state production operations, allows mistuned tools to be quickly located and diagnosed and also significantly reduces the labour costs required during such activities.

Features

- Supervisory visualization and analysis across your entire facility, shown by line, tool, shift and time period

- SPC charts for all data

- Event capture and annotation

- Throughput, efficiency, and yield cause/effect display and drill-down

- Quantitative linkage of observed IV variations to actual upstream process variations

- Intuitive visual dashboards and tools

- MES interface

- Uses IV data alone or (coming soon) in combination with other measurements

- Industry 4.0 compliant

Benefits

- Increased throughput by predictive maintenance scheduling and optimal material routing

- Cost -effective problem detection and qualification in raw materials

- Faster, more accurate line ramp-up, optimization and troubleshooting

- Reliability, speed and confidence in scaling operations while meeting or exceeding yield targets

- Rapid, accurate detection and root-cause resolution of variations or problems in IV result

- More profit and better KPI results by boosting yield without added complexity or tool upgrades/additions

Insight is available as a server-based software product that is easily and securely installed and operating in your cell production facility. It communicates with your existing IV-testers and provides a web-based user interface for plant-wide access and usage